High lifting reach and solid stability: Guan Chuan Engineering uses telescopic crawler crane SENNEBOGEN 6133 E for Singapore's Deep Tunnel Sewage System Project

Singapore is a global pioneer in sustainable water management and invests heavily in its Deep Tunnel Sewerage System (DTSS). In the meantime, the major construction project has entered its second phase, which should be completed by 2025. With earth retention – through metal sheet piling – being an important part of the project, a key challenge is making sure the silent piler main body does not move while the Larssen interlocking sheet pile is being slid in. A task for which the specialist silent piling technology and foundation engineering company Guan Chuan Engineering chose the SENNEBOGEN 6133 E telescopic crawler crane.

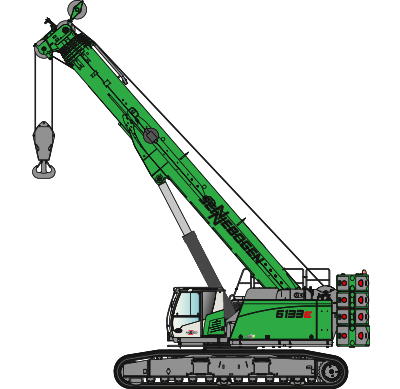

Holding up the silent piler main body, the pile auger and sheet pile often exceed 20 tons in weight. This is a common scenario in deep tunnel excavation work like building a sewerage system from scratch at one of the tunneling shafts at Penjuru Road in Singapore. Led by Guan Chuan Engineering Construction, the ongoing DTSS project currently has the 6133 E crane in place, the largest telescopic crawler crane to date in the SENNEBOGEN product line.

The second phase of the superhighway construction includes a combination of 60 km of link sewers, a 30 km used water tunnel in the South (domestic) and a 10 km industrial used water tunnel across the west of Singapore. Dominating the project is transporting waste and used water to Centralized Reclamation Plants located near the coastal areas, wherein waste and used water will then be purified to high-grade clean recycled water.

With close to 40 years of experience in boring rigs within the city center and silent piling in perilous conditions, Guan Chuan Engineering Construction specializes in quality Earth Retaining or Stabilizing Structure solutions in Singapore. With SENNEBOGEN crane and material handling distributor ALY Energy providing service support, they have given Guan Chuan Engineering Construction the confidence to own and operate a huge variety of SENNEBOGEN telescopic crawler cranes like the 613, 653, 683, 6133 E and among others.

The decision for the new SENNEBOGEN 6133 E was made at the trade fair bauma 2019: "The design of the machine and especially the load capacity and reach height convinced us immediately and we were sure that the 130-tonne crane is the ideal addition to our fleet", Liaw explains.

Robust construction – maximum stability and safety

In construction projects of this kind, stability and safety of the machine are particularly important. The SENNEBOGEN 6133 E is equipped with a 6-section 52 m main boom. A reach height which allows the auger and sheet pile being held steadily upright. With the optional 15 m fly jib, even reach heights of almost 70 m can be achieved.

Maximum stability is ensured by the crawler undercarriage which can be telescoped to 5.40 m track width. Technical features, that convince: „Holding on to the silent piler main body while lifting and sliding in the sheet piles is often challenging. With SENNEBOGEN’s quality boom structure, I only need to focus on sliding in the steel plate, nothing else”, explains Guan Chuan crane operator Mohamad Hamid.

Another important safety factor is the SENNEBOGEN Maxcab, which comes with large glass windows as standard and can be tilted by 20°. Whether having the load or the safety supervisor in view, who gives important instructions: A good visibility of the working area can be crucial.

Self-assembly system saves time and costs

Anyone who has worked on large construction sites knows how tight schedules are and how precisely tasks and personnel must be planned. Manimozhi Muthukumar, site supervisor, keeps track of all tasks and is responsible for ensuring that each worker knows exactly what to do. One of his greatest challenges is to save time or use it as efficiently as possible. A great help in daily operation: The SENNEBOGEN 6133 E telescopic crawler crane can remove and re-attach its own track undercarriage with a remote control, in addition to loading and unloading its counterweight. “There is no delay and no need for extra manpower. The SENNEBOGEN 6133 E can retract its 5.40 m wide track to 4 m for self-loading to the low-loader”, Muthukumar emphasizes. The arrival of the SENNEBOGEN 6133 E allowed him to maximize his existing manpower due to the increased mobilization and demobilization process.

“An additional machine in the job site is an additional task on my list. With the SENNEBOGEN 6133 E, there isn’t a need to have auxiliary cranes to carry out mobilization and demobilization. This makes my work a lot easier so I can safely focus on deploying my men around the site”, he continues.

It is not only because of their easy transport that telescopic crawler cranes – such as the SENNEBOGEN 6133 E – are becoming increasingly popular on construction sites. They can be used for a variety of tasks, are maneuverable on difficult terrain and also suitable for narrow construction sites. Depending on local conditions, they can move loads using the Pick & Carry principle. "With our telescopic crawler cranes we are simply more flexible. This allows us to work much more efficiently as compared to working with conventional machines", David Liaw summarizes.

Machine in use

Press images

Press images

Press images